Class Societies

On a regular base we receive the question if MXSuite has a type approval. This article describes what a type approval is and what the requirements of a planned maintenance system (PMS) in general are with the special requirements for software.

MXSuite is accepted by all class societies.

Let me first explain what a type approval is. Classification societies make sure that the quality and safety on board and other places are secured and trustworthy. For that purpose they perform audits / inspections of designs and constructions. The word ‘constructions’ should be interpreted in a broad sense.

Explanation common practice

Example of an anchor

Let me give an example of a simple product as an anchor. The steel quality needs to be verified. So production till rough steel product needs to be verified.

If you want to sell your anchor for a vessel that is classified, than your anchor needs to be classified as well. Your anchor design needs to be approved before you can produces it. If you cast your anchor stock, you need to do this according the official regulations to secure the stock will have the right material properties. So a class surveyor will attent this procedure and will approve this sub product stamp. You can imagine this applies to the whole production process. Now you have an anchor which is according your building instructions and that you can use onboard of a vessel.

The advantage of a type approved anchor

If you apply for a type approval, than you will gain several benefits over your design and production. First of all you do not need to send in every production design. Secondly, if your anchor has good holding properties and this is proven by testing under supervision of a surveyor, you may reduce the weight of the anchor.

The benefits for the manufacturer are: less paperwork, approved design can be re-used and the weight reduction gives him a huge commercial advantage.

The benefits for the client are: 1.) less weight so its cheaper and 2.) trustworthy product.

Type approved software

The rules of the class societies give the option to use a type approved PMS system, or a case by case approved system. Strange enough, the benefits of type approved software are not mentioned.

The Planned Maintenance System is a paper/software-based system which allows ship owners or operators to carry out maintenance in intervals according to manufacturers and class/Classification society requirements. The maintenance, primarily supervised by the on board personnel, is then credited towards inspections required by periodic surveys. The planning and scheduling of the maintenance, as well as its documentation, must be made according to a system that is approved by classification societies. All classification societies are members of IACS (International Association Of Classification Societies Ltd). Having a planned maintenance system on ships is now mandatory as per ISM (International Safety Management Code).

There is a document describing the requirements from IACS. For this document the IACS requirements 2012 are used.

Chapter Z20 of this document describes the requirements for PMS for machinery. PMS stands in this document for Planned Maintenance Scheme. So a scheme can be used on paper, in Excel or in a computerized system like MXSuite.

Reading chapter Z20, the following can be found regarding computerized systems:

“Access to computerized systems for updating of the maintenance documentation and maintenance program shall only be permitted by the chief engineer or other authorized person.”

Paragraph 1.3.3

✓ MXSuite contains User Access Control, so fits to this requirements.

“The PMS shall be programmed and maintained by a computerized system. However, this may not be applied to the current already approved schemes.”

Paragraph 2.1.1

✓ This paragraph is part of the section describing the procedures and conditions for approval of a PMS. So, when setting up a new planned maintenance scheme, this paragraph forces you to use a computerized system like MXSuite.

“The system shall be approved in accordance with a procedure of each individual Member Society.”

Paragraph 2.1.2

The system means the PMS in a computerized system. So this refers to a procedure of each individual member (= classification society like LR, GL, DNV, BV, etc.)

“Computerized systems shall include back-up devices, such as disks/tapes, CDs, which are to be updated at regular intervals.”

Paragraph 2.1.3

✓ MXSuite offers the possibility to create a backup file. Also at database level, a backup can be created. Next to this, if an MXSuite installation is synchronizing data to an office, this can be seen as a backup.

Paragraph 2.2 describes the documentation and information to be submitted for approval. This paragraphs describes only items related to the planned maintenance scheme onboard of the ship, and really nothing regarding software

ISM Code requirements

ISM Code requirements

Chapter 5, section 10 of the ISM Code describes also something about “maintenance of the ship and equipment”. Reading chapter 5, section 10, nothing found regarding computerized systems. Chapter 5, section 10 describes in short:

- That the equipment and ship is maintained conform the relevant rules

- Regular inspections are carried out

- Non-conformities are reported

- Appropriate corrective action is taken

- Records of all activities are taken

- Critical equipment should be defined

There is a document: “Approval of Computerized Maintenance Management System used on board ships” with version number: NR 496 DTM R01E We’ve contact Bureau Veritas with the question if it is required to have this approval for MXSuite. We’ve received the following answer:

Until the “January 2012 Amendments” became in force it was a requirement that the PMS software should be type approved. Presently the following is required as per rule reference Pt A, Ch 2, App 1 – 2.1.2 “The Owner himself is to confirm to the Society, by written declaration, that the required functionalities of the system are met. Or, alternatively, the Society may approve the software upon specific request.”

In short “type approval” is not a requirement any longer!

✓ MXSuite meets the requirements which are described in the document “Approval of Computerized Maintenance Management System”. Beside that a “type approval” is not required anymore.

The DNV regulations 2021 state the following:

- The software shall be computer based.

- The software shall include at least the applicable machinery and equipment listed in Sec.4 Table 26. All these components shall be identified as class items in the software.

- The software shall be able to produce a maintenance history report of maintenance carried out for a specific time period on class items.

- It shall be possible to identify and trace corrective maintenance in the software. All damage/break-downs on class related machinery items shall be reported to class.

- For ships with class notation E0, AUT or ECO, the software shall include the periodical testing of control, alarm and safety components and systems required by relevant rules. These jobs shall be especially identified in the software and include test routines and set-points based on relevant rules.

- Changes to the software (maintenance intervals, job descriptions, etc.) shall be traceable and documented and presented to the attending surveyor at the next annual survey for acceptance.

- Guidance note 1:

Documentation in order to adjust maintenance intervals, job descriptions, etc., may be accepted by attending surveyor on the basis of maintenance reports, wear measurement forms, service letters from maker, etc.

—e-n-d—o-f—g-u-i-d-a-n-c-e—n-o-t-e— - The job descriptions for all the machinery and equipment subject to class shall be available either as part of the planned maintenance system and/or as specific reference to makers’ manuals. The extent of the job descriptions either within the PMS or in the referred manual shall be self-explanatory. When references to maker’s manuals are made, these shall be ready available onboard.

- The job descriptions and maintenance history shall be in English.

- Back up of the PMS database, making it possible to restore all data, shall be taken at least once a week.

- Job intervals shall be based on maker’s recommendations, adjusted for prevailing operational conditions. Deviations from initial intervals shall only be accepted when documented experience can justify changes.

MXSuite complies with all the demanded class regulations.

All the blue marked items in the regulations above are completely met by MXSuite. What strikes is that most requirements do not have anything to do with the software itself.

There are several documents from Lloyd’s Register related to PMS. All relevant documents about this subject, are made anywhere in range from 2004 – 2006 and never updated since!

Hull Planned Maintenance

In this document, the “s” of PMS stands for Scheme.

“The scheme to be based on a computerised system with arrangements for backing up data at regular intervals. Access to computerised systems for updating of the maintenance documentation and maintenance programme shall only be permitted by the Chief Engineer or other authorised person(s).”

Paragraph 2.3 under the part for Operational Requirements:

✓ MXSuite offers the possibility to create a backup file. Also at database level, a backup can be created. Next to this, if an MXSuite installation is synchronizing data to an office, this can be seen as a backup.

✓ MXSuite contains User Access Control, so fits to this requirements.

“The administrative functions of a computerised system are essentially no different from older card index systems, although there are certain additional advantages to be gained.”

Appendix A2 describes also something about computerized systems.

✓ Make my day! LR is doing advertisements for MXSuite!

Software conformity assessment system

This document describes the rules for a software product for Planned Maintenance Schemes. The requirements for the software are mentioned in this document. The requirement specification roughly can be divided into 2 parts:

- Specific software requirements

- General PMS requirements

The specific software requirements contains the 2 well known issues: user right control and backup. On top of this, user documentation (user manuals) are important stuff here. The general requirements includes the general requirements for planned maintenance schemes, and includes also the option to offer training to the on board crew.

Conclusion

There are different explanations of PMS. In general, the “s” could mean Software, System or Scheme.

When the “s” means Software, it is described as a “Computerized System” in the relevant documentation of the IACS and Class documentation. There are 2 requirements which are related to computerized systems:

- The software should have the possibility to make a backup.

- There should be a way of user access control.

In both cases MXSuite complies to the requirements.

Backup

MXSuite has a build-in option to make a backup of all data in the database. The backup can be created via the MXSuite interface, and saved at any file location. The second option to make backups is to backup the Microsoft SQL database. For this a scheduled task can be created, to execute the backup process at a regular base. Last but not least, MXSuite offers the possibility to synchronize the data to an office. All data which is in the database of the ship will be synced to the office. A daily backup of the office database is recommended, in order to securely keep all data.

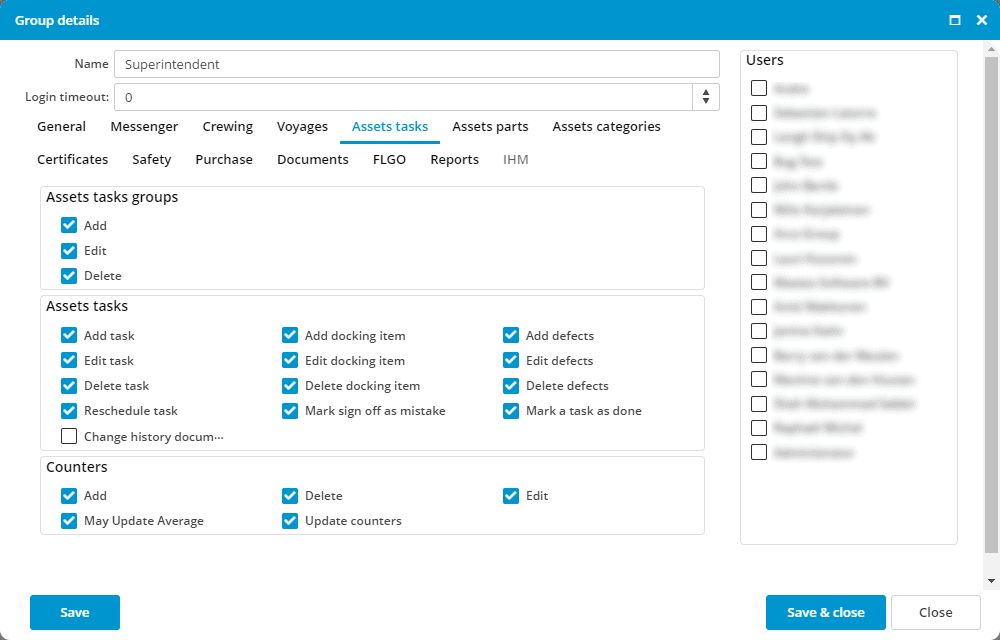

User access control

When MXSuite is started, the user has to login in the software using an username and password. Without correct username and password, login is prohibited.

All users will have their own user rights for each part of MXSuite. Especially for the maintenance module, there are a lot of user rights.

Practicality

After a thorough investigation we came to the conclusion there is no benefit for the PMS system to acquire a type approval. It is even worse for you, the owner, or manager, because the live onboard audits are still required. After speaking with several surveyors they confirmed that they would not do anything different during their inspections.

ISM Code requirements

ISM Code requirements